Co-Extrusion

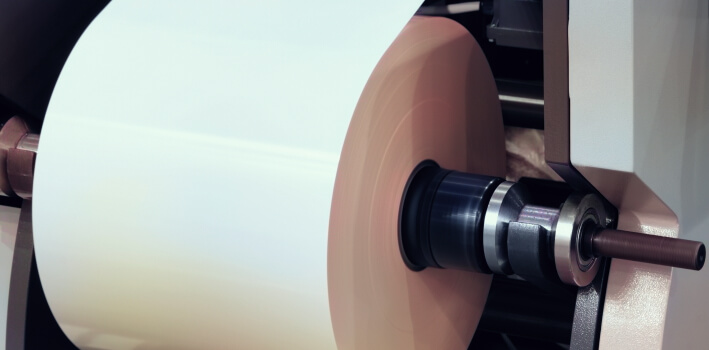

Our extrusion process involves feeding plastic resin into state-of-the-art extruders, which transform the raw material (polystyrene, polypropylene, or ABS) into multi-layered films tailored to the desired specifications.

With the capability to produce up to five layers, our advanced extruders are operated by a skilled and experienced team. These machines, procured from leading global manufacturers, represent the latest technology and adhere to the principles of a circular economy, ensuring efficient and sustainable production practices.

Thermoforming

The production of cups and lids is facilitated through the thermoforming method, utilizing molds installed in specialized machines. This process is diligently executed by a dedicated and experienced team, with oversight from our quality assurance personnel to ensure strict compliance with ISO 9001:2015 and HACCP standards. Our commitment to adhering to these stringent guidelines is unwavering, reflecting our dedication to delivering products of the highest quality.